How DFN uses fully connectorized solutions to get fiber to their customers faster

Douglas Fast Net (DFN), a subsidiary of Douglas Electric Cooperative, serves customers in central Oregon’s Douglas, Coos, and Lane counties. Their broad serving area stretches from the Oregon coast to the hills and mountains of rural Oregon, including cities like Roseburg and Eugene. DFN’s network spans thousands of miles of fiber and DFN prides itself on being 100% local. Todd Way, CEO of DFN, describes their long-term strategy as “fiber-to-the-everything,” serving their neighbors with the best connection possible while—as a cooperative—returning a dividend to their members. DFN was among the first companies in the nation to offer Gig-speed residential service and they hope to introduce 10 Gig service in the future.

A discovery process

With a fiber network in constant development for years, DFN has learned which tools enable the simplest, most efficient deployment to the varied communities they serve. Unlike some companies, which may provide service solely to urban areas or only in relatively remote rural locations, DFN’s communities have a mix of density and dispersion. Over the years, trial and error has given DFN a clear sense of the best solutions for each of their unique locations.

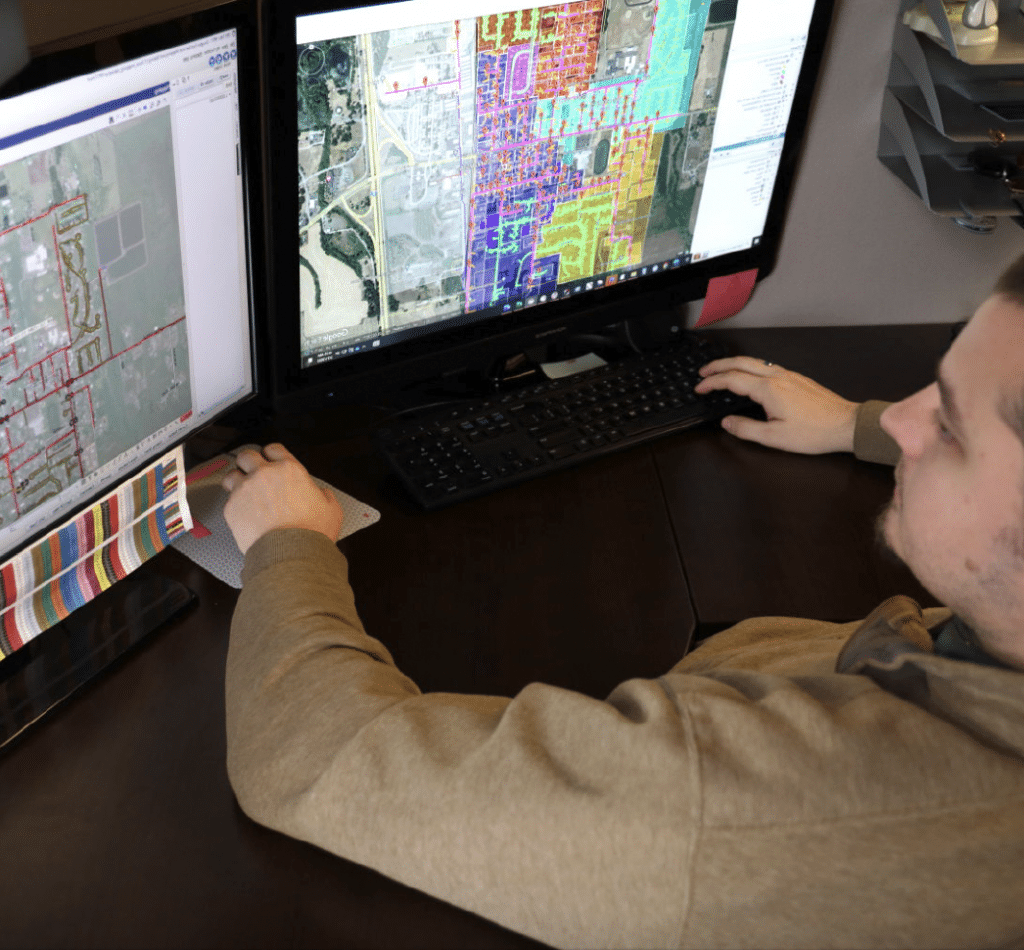

For fiber builds in denser communities, like small cities and suburbs, DFN relies on Corning’s FlexNAP™ system to provide the most adaptable and user-friendly fiber construction process possible. To configure the preconnectorized system, DFN embraced a new method of data collection with a change in upfront planning that pays off down the line. The increased forethought that’s now part of their design process results in time savings when it’s time to place fiber.

Experiencing the benefits of FlexNAP

DFN saves substantially on splicing costs thanks to FlexNAP’s fully connectorized Evolv terminal solution, enabling quick and efficient network deployment without specialized training. While the splicing techs on the team were initially worried about whether FlexNAP would put their jobs on the line, Todd Way reports that DFN’s ongoing fiber construction allows their splicers’ time to be used more efficiently in areas where traditional methods are still employed.

DFN has discovered other benefits of the FlexNAP system beyond the flexible, efficient, easy-to-use cable technology itself. For example, because Corning invests in ample amounts of FlexNAP, DFN has not been plagued by supply chain issues that other broadband service providers face. Also, since each cable is custom-made for specific deployment areas, DFN has greatly reduced the amount of scrap fiber cable they discard.

Corning’s support extends beyond the FlexNAP product. DFN leverages Corning’s engineering services team, which offers a detailed design review of how the FlexNAP system will be deployed to ensure the design is accurate and optimized, and the correct materials are ordered. This quality check results in efficient construction that minimizes deployment delays.

The net result: Faster deployment, happier members

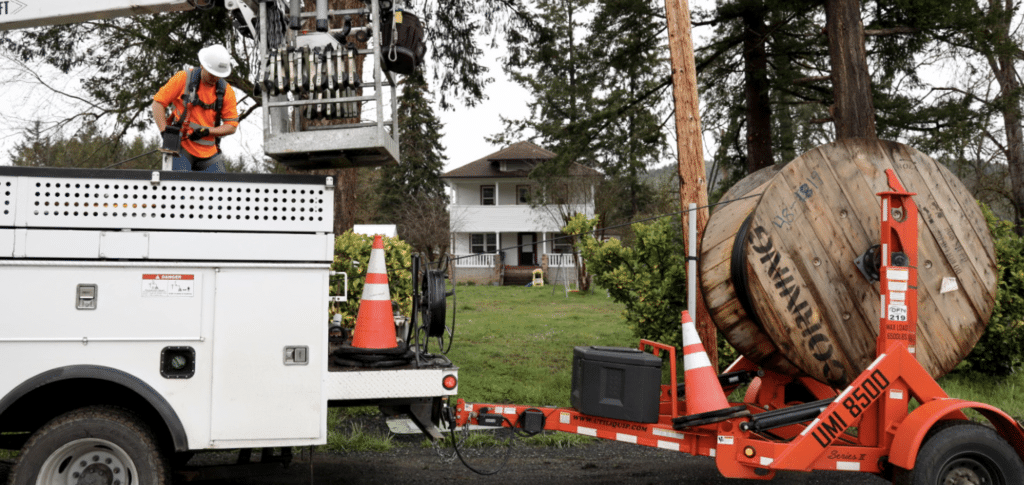

The ultimate test of the FlexNAP system is whether it results in a quicker time to market and—after making necessary internal adjustments and becoming savvy to the preconnectorized system—DFN reports greatly improved deployment time. DFN’s fiber buildout to a new community takes less time than it did before FlexNAP: it’s estimated that FlexNAP saves approximately 64 splicing hours. “We used to hang fiber and then wait six to eight weeks for splicers,” says Todd Way, but those days are in the past. FlexNAP has enabled DFN to have services ready for connecting customers in one week versus six to eight weeks using traditional splicing deployment techniques. The reduction in time and splicing has resulted in an overall savings of 30% in their network deployment cost. Way guesses that, had DFN started using FlexNAP and realized its benefits sooner, they may have built out their network to denser areas earlier. Today, DFN fully appreciates the overall value of the preconnectorized system.

In the end, DFN’s customers are getting connected faster. When a potential subscriber already has a terminal located near their home, their fiber connection can be installed as soon as the technician gets the service add request. Connecting a customer with the preconnectorized system takes a matter of hours—not days, as with traditional splicing. Corning’s FlexNAP system is helping DFN live out its corporate values: keeping “customers connected to the world and each other” and “offering speeds and reliability once reserved for those in the big city.”